PTFE dust bag for industrial use

Basic Info

Model No.: BOOD-141

Product Description

Filter bag section shape

According to the shape of the filter bag, it can be divided into three types: circular, flat and irregular.

1, round: dust filter bag is cylindrical. Its specifications are expressed in diameter by D * L (mm).

2, flat: filter bag is flat, including rectangle and trapezoid, and its specifications are expressed by circumference * length (P * L (mm)).

3, aliens: shape specific filter bags, whose specifications are expressed in terms of their structural characteristics.

Four. Filtering method

According to the filtration way, it can be divided into two types: internal filtration and external filtration.

1. Internal filter bag: the dust containing gas filtered through the inner surface of the filter bag, and the dust is obstructed on the inner surface of the filter bag. This filtration method is called internal filtration.

2, external filter filter bag filter bag: dust gas is filtered through the outer surface of the filter bag, and the dust is separated on the outer surface of the filter bag. This filter is called the external filter type.

According to the processing method, it is mainly divided into three parts: woven filter cloth, dust bag, nonwoven filter cloth and duster filter bag.

1, woven filter bag filter: using looms to vertically arrange yarn and weft yarns which are arranged vertically according to a certain organization rule, in the letter W.

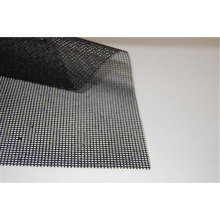

2, non-woven filter bag filter bag: without the general spinning and weaving process, the fiber into a net or yarn into a layer, interlaced, glued, needled, melted or spinning sheet filter material, with the letter NW and the specific processing method of the composite letter of the letter;

3. Composite filter cloth bag: filter bag made of more than two methods or made of two or more materials, which is written in letter C.

Fabric tissue

According to fabric organization, it can be divided into three types: plain cloth filter, dusting cloth bag, twill filter material and forge grain filter material.

1, flat texture: This is the simplest form of weaving, each of the warp and each of the weft is alternating, but the plain texture is difficult to clear ash and easy to clog and other shortcomings, therefore, the weaving organization has been rarely used as a filter material;

2, twill structure: it is made of two roots and four warp yarns are interwoven with the weft yarn. The weft yarn interlacing points gradually move to the left or right; the twill is divided into single and double twill. The flexibility and elasticity of the twill fabric are superior to the plain weave, the mechanical strength is slightly lower and the force is easily misplaced after the force, but its wear resistance is good and dust removal The efficiency and cleaning effect are also good, which is the most commonly used organization of woven filter media.

3. Forged texture: the warp or weft can be divided into warp and weft forged lines on the surface of the fabric. The forged texture is characterized by smooth, glossy, very soft, flexible and breathable, and easy to remove ash due to the mobility of the yarn.

Contact us if you need more details on Raymond Mill Bag. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Vertical Mill Dedusting Bag、Anti Electrostatic Precipitator Bag. If these products fail to match your need, please contact us and we would like to provide relevant information.

According to the shape of the filter bag, it can be divided into three types: circular, flat and irregular.

1, round: dust filter bag is cylindrical. Its specifications are expressed in diameter by D * L (mm).

2, flat: filter bag is flat, including rectangle and trapezoid, and its specifications are expressed by circumference * length (P * L (mm)).

3, aliens: shape specific filter bags, whose specifications are expressed in terms of their structural characteristics.

Four. Filtering method

According to the filtration way, it can be divided into two types: internal filtration and external filtration.

1. Internal filter bag: the dust containing gas filtered through the inner surface of the filter bag, and the dust is obstructed on the inner surface of the filter bag. This filtration method is called internal filtration.

2, external filter filter bag filter bag: dust gas is filtered through the outer surface of the filter bag, and the dust is separated on the outer surface of the filter bag. This filter is called the external filter type.

According to the processing method, it is mainly divided into three parts: woven filter cloth, dust bag, nonwoven filter cloth and duster filter bag.

1, woven filter bag filter: using looms to vertically arrange yarn and weft yarns which are arranged vertically according to a certain organization rule, in the letter W.

2, non-woven filter bag filter bag: without the general spinning and weaving process, the fiber into a net or yarn into a layer, interlaced, glued, needled, melted or spinning sheet filter material, with the letter NW and the specific processing method of the composite letter of the letter;

3. Composite filter cloth bag: filter bag made of more than two methods or made of two or more materials, which is written in letter C.

Fabric tissue

According to fabric organization, it can be divided into three types: plain cloth filter, dusting cloth bag, twill filter material and forge grain filter material.

1, flat texture: This is the simplest form of weaving, each of the warp and each of the weft is alternating, but the plain texture is difficult to clear ash and easy to clog and other shortcomings, therefore, the weaving organization has been rarely used as a filter material;

2, twill structure: it is made of two roots and four warp yarns are interwoven with the weft yarn. The weft yarn interlacing points gradually move to the left or right; the twill is divided into single and double twill. The flexibility and elasticity of the twill fabric are superior to the plain weave, the mechanical strength is slightly lower and the force is easily misplaced after the force, but its wear resistance is good and dust removal The efficiency and cleaning effect are also good, which is the most commonly used organization of woven filter media.

3. Forged texture: the warp or weft can be divided into warp and weft forged lines on the surface of the fabric. The forged texture is characterized by smooth, glossy, very soft, flexible and breathable, and easy to remove ash due to the mobility of the yarn.

Contact us if you need more details on Raymond Mill Bag. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Vertical Mill Dedusting Bag、Anti Electrostatic Precipitator Bag. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Dusting Bag

Hot Products

3732-130P1 PTFE Coated Fiberglass Fabrics3788HT Heat Treated Fiberglass FabricsFW800WLBL Weave-lock Fiberglass FabricsFGW3000V Vermiculite Coated Fiberglass FabricsFW800AL Aluminum Laminated Fiberglass FabricsHSIF3786 High silica Fiber FabricWF Texturized Fiberglass Fabric3788 E-Glass Filament FabricPTFE Adhesive TapesPTFE Adhesive TapesSkived PTFE Tapes3000ACBLY Acrylic Coated Fiberglass Fabrics Welding Blanket2025ACBLY Acrylic Coated Fiberglass Fabrics Welding BlanketPTFE Architectural MembraneCFGRPT Ceramic Fiber Twisted RopeSISL High Silica Fiber Sleeve